Brokk Descaler – the solution to avoid hazardous descaling

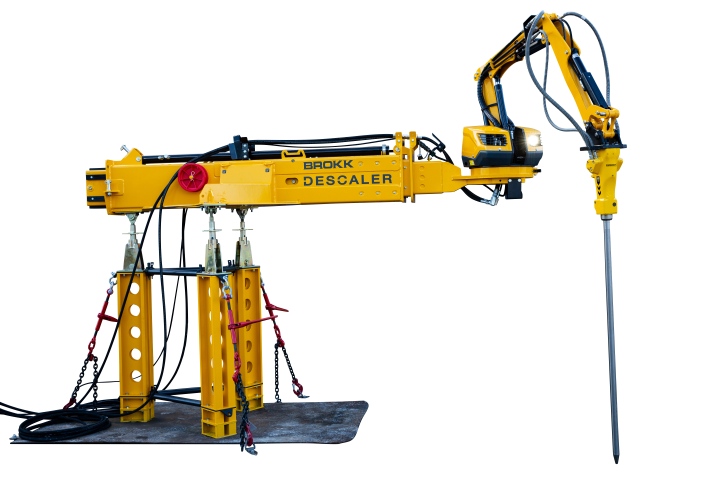

With a telescopic boom for outstanding reach and remote controlled maneuvering, the Brokk Descaler revolutionizes the working method for tearing out overhead material in preheater towers. A solution that makes the work safe and efficient, something that was previously impossible. Safe descaling – with zero people inside.

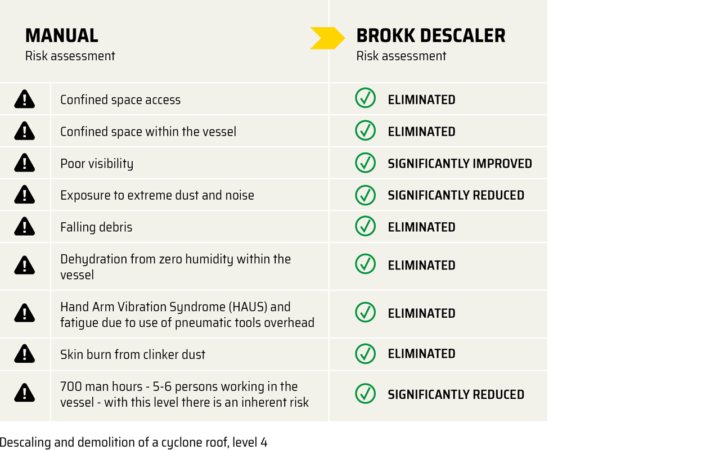

Health and safety is a constant challenge and an important issue for cement plants around the world. Removing workers from hazardous areas has been an ongoing process for the past 40 years and Brokk robots has already put many workers in safety in cement kilns and coolers thanks to the remote controlled maneuvering. Similar issues with overhead refractory and coating has been the case in preheater towers for years but without a safe and efficient working method.

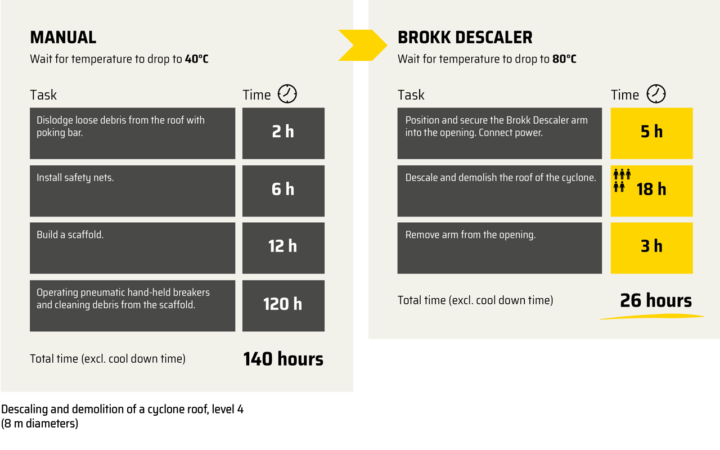

The conventional method often involves manual pre-inspection before sending workers in on scaffoldings with handheld breakers making it both risky and time consuming. The workers are not only exposed to the risk of falling debris but also the silica dust that gets into the body and skin. Furthermore the vibration from handheld tools is a known problem and causes “white fingers”.

The Brokk Descaler evolved from the Brokk robot, allowing for tearing out refractory, coating and build-up without any workers entering the preheater tower. By doing so a number of risks have either been completely eliminated or significantly reduced.

Applications

Anywhere there is build-up there is work for the Brokk Descaler:

- Pyrotop

- Cyclones

- Calciners

- Roof of gas risers

- Kiln inlets

- ”Goose neck”

- Alumina calciners, silos etc.

Installation

The Brokk Descaler allows for a quick installation in less than 3 hours and is easy to mobilise to any location in the tower as it can be transported in most passenger lifts. Once installed the operator can safely overview the work from outside of the vessel through hatches, which allows for precise and controlled demolition.

Hundreds of tons of overhead refractory can be removed with zero physical contact and at a much faster pace than doing the same task manually. This ensures high productivity as well as safety for the workers. Ultimately, a safer and more efficient worksite.

Safety:

- Safe descaling with zero people inside

- Access from different positions with optimal view for operator

- Minimize workers being exposed to dust

Increased productivity:

- Reduce shut down time – improve production capacity

- Install at any level in less than 3 hours

- Move quickly between platforms in lift

Once you’ve seen the benefits of using the Brokk Descaler there is no going back to the very riskful methods previously used.

Technical data for Brokk Descaler Single and Brokk Descaler Twin.

Read the press release about the Brokk Descaler.

Thank You!

Thanks for your message. We’ll answer as soon as possible!

// The Brokk team