Cement Remote-controlled reduction of plant downtime

Brokk demolition robot – The fastest and safest cement industry solution

Demolishing coating and brick linings is an ideal task for the Brokk demolition robot, offering unparalleled speed and safety. The robot’s compact design allows for easy access, while its remote-controlled nature ensures that the work is conducted safely and efficiently. The operator can choose the best position for performing and monitoring the work, free from concerns about vibrations, fumes, or the risks associated with collapsing material or hot coatings.

The Brokk robot boasts excellent stability in all directions and features an easily adjustable breaker frequency, ensuring precise operation without damaging the shell or lining. Its three-part arm system provides exceptional flexibility and reach, requiring less repositioning than conventional excavators.

The heat-resistant design of the Brokk demolition robot, coupled with well-protected cylinders and components, allows work to begin earlier, reducing the risk of heat-induced breakdowns. This capability minimizes plant downtime and enhances overall plant profitability.

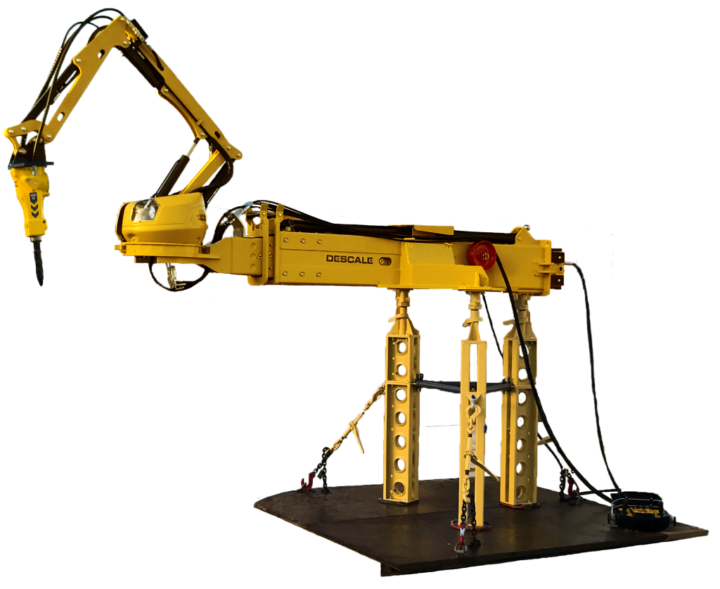

Brokk Descaler

The Brokk Descaler sets a new standard in removing overhead refractory in preheater towers, combining a telescopic boom for outstanding reach with remote-controlled maneuvering. This innovation transforms descaling work, making it safer and more efficient—previously an impossible feat. With the Brokk Descaler, the task can be performed with zero personnel inside the hazardous area.

Traditional methods require manual pre-inspection and the use of handheld breakers on scaffolding, a process fraught with risks and inefficiencies. The Brokk Descaler eliminates the need for workers to enter the preheater tower, significantly reducing or eliminating various risks associated with manual descaling.

Safety:

- Zero Personnel Inside: Safe descaling with no workers inside the hazardous area.

- Optimal Visibility: Access from various positions with the best view for the operator.

- Dust Reduction: Minimizes workers’ exposure to dust.

Increased productivity:

- Reduced Shutdown Time: Shortens plant shutdowns and boosts production capacity.

- Quick Installation: Can be set up at any level in less than 3 hours.

- Efficient Mobility: Moves swiftly between platforms using a lift.

Read more about the Brokk Decaler here.

Reasons to choose Brokk in the cement industry

FAST & EFFICIENT

FLEXIBLE & PRECISE

SAFE & ERGONOMIC

HEAT-RESISTANT

Cement: Popular products

Contact Form

Thank You!

Thanks for your message. We’ll answer as soon as possible!

// The Brokk team