Brokk SmartConcept Three secrets behind your new advantages

BROKK SMARTPOWER

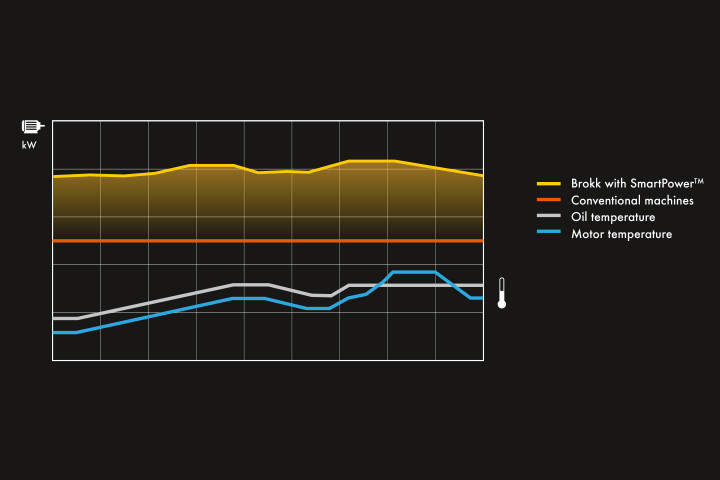

With Brokk SmartPower™, you get the world’s most intelligent power system, designed specifically for heavy duty demolition. The secret lies in a system that offers increased power through a smart control and monitoring system and a hardened electrical design – maximizing production while minimizing downtime. It is the answer to the seemingly impossible equation of making machines more powerful than ever, yet so compact and lightweight that they can access the tightest confined spaces. The robustness also provides nonstop operation even in hot or other extremely demanding environments. Brokk SmartPower™ outsmarts the limitations. The all new intelligent power management introduces a unique electric powertrain that increases the output in any given size of power pack by 50% or more. The smart monitoring makes the Brokk machine well-suited to work in environments with generators or potentially unreliable power supply. The intelligent system senses if the power supply is poor or faulty, compensates for it as much as possible and then protects the components before any harm is done. This extends the lifetime of all electrical and hydraulic components. The unique design and smart modifications of key components also contributes to the unparalleled reliability. Compared to a traditional system, internal cabling and contacts are reduced to an absolute minimum (a 70 percent reduction). With no moving parts in the electrical system and components designed to withstand extreme vibrations, dust and rough handling, the system is perfect for the working conditions of a demolition robot.

BROKK SMARTDESIGN

Brokk’s new machine design focuses on facilitating the operator’s everyday handling of the machine. By making service and maintenance easier than ever, we maximize uptime and create a troublefree and productive experience throughout the entire product lifespan. That’s why all daily and weekly maintenance can be carried out without lifting a machine cover. That’s why all greasing points, including the breaker grease refill, are easily accessed from the outside. That’s why we eliminated the need for regularly tightening shafts that are hard to reach. That’s why hose replacement on a Brokk machine now is so easy, and why outrigger hoses are divided so only a short section needs replacement if damaged by rebar or other debris. The new hardened design also protects the machine and minimizes damage if and when accidents do occur, which reduces repair costs and increases uptime. With pressed steel covers that resists damage. With casted turn-table corners and rugged LED-lighting protection, etc, etc.

BROKK SMARTREMOTE

Ergonomics is one of many advantages with remote controlled demolition. The ability to choose a comfortable working position away from vibrations, heat and debris, and still have a perfect view of the situation. Brokk takes this one step further with SmartRemote™. Yes, there are other remote-controlled solutions. But all remotes are not created equal. Brokk’s SmartRemote is industry-leading in its ergonomic design and its features that make the operator more productive. We have thought of every detail: The professional radio technology provides reliable and fast connection with the machine up to a distance of 300 meters, making sure that the operator can choose a good position. A patented waist harness shifts weight to where it belongs, relieving stress on shoulders. Short joysticks allow operators to rest their arms on the remote control, reducing strain. Intuitive controls allow operators to focus on the work, without the need to look at the remote for operation. At Brokk, we know that the machine and the operator work as a team. That’s why we designed a remote control system that helps the operator stay productive throughout a long work shift and helps him stay healthy over the long term.

Thank You!

Thanks for your message. We’ll answer as soon as possible!

// The Brokk team