BROKK 130+

The Brokk 130+ sets a new benchmark in demolition, delivering more power, endurance, and efficiency than ever before. Designed for demanding environments, it combines high impact energy with intelligent power management, making it ideal for confined and hard-to-reach areas. With a 360-degree working radius, it ensures maximum flexibility in any operation.

Equipped with the BHB 175 breaker and the advanced Brokk SmartPower+ system, the Brokk 130+ maximizes efficiency for superior demolition performance. It delivers 20% more hitting force and 40% higher impact frequency, boosting production by 40–60%. Every movement is precisely controlled for smoother operation, greater force, and optimized productivity.

- Increased uptime and power over time

- Smart sensors and operator support system

- Lightweight control box with tilted joysticks

- 20.2 kW Brokk SmartPower+ electrical system

- Compatible with 16A and 32A fuses for flexible power options

Features

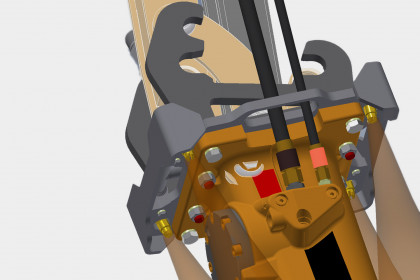

Brokk QuickSwitch

Visual Status Communication System

Ergonomic control box

Brokk SmartPower+

- Hydraulic breaker in illustrations.

Load and stability diagram available on request. - BHB 175

Performance

- Slewing speed

- 10 sec/360°

- Transport speed, max.

- 2.5 km/h; 1.6 mph

- Climbing inclination, max.

- 30°

Hydraulic system

- Hydraulic system capacity

- 40 l; 10.6 US gal

- Pump type

- Variable load-sensing

- System pressure

- 18 MPa; 2611 psi

- Pump flow 50Hz

- 56 l/min; 14.8 US gal/min

- Pump flow 60Hz

- 66 l/min 17.4 US gal/min

Power system

- Power technology

- Brokk SmartPower+

- Electric motor type

- ABB

- Power*

- 20.2 kW

- Recommended fuse size*

- 32 A

- Minimum fuse size (reduced power)*

- 16 A

- Starting device

- Soft start

Control system

- Control type

- Portable

- Signal code

- Digital

- Transfer

- Professional radio/Cable

- Range, radio

- Up to 300 m

Weight

- Machine weight**

- 990 kg; 2183 lbs

- Recommended attachment weight

- 180 kg; 397 lbs

Noise level

- Sound power level LWA***

- 91 dB(A)

- Width min.

- 780 mm; 30.7 in

- Height min.

- 1160 mm; 45.7 in

- Vertical reach (incl. breaker)

- 4300 mm; 169 in

- Horizontal reach (incl. breaker)

- 3700 mm; 146 in

*Valid for 400 V/50 Hz and 440 V/60 Hz

**Excluding options and attachment

***Measured according to directive 2000/14/EC, excl. attachment